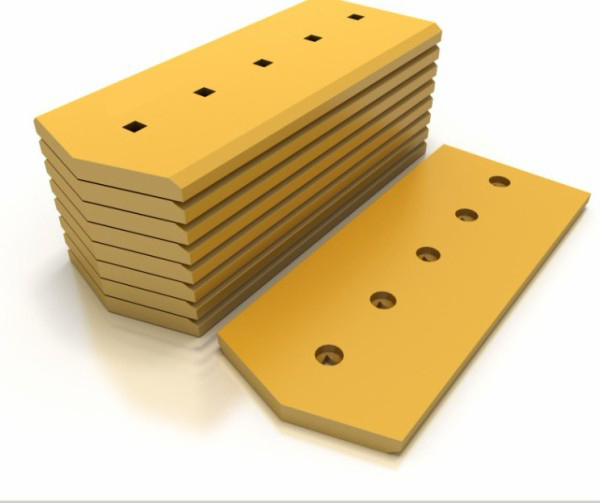

How to choose a solutions between flat grader blade, tungsten tip grader blade, serrated grader blade?

About how to choose a grader blade. It's really dependent on your application and what you are using the grader blade

doing. A mine working environment will generally use thick flats to maintain haul roads, road building and final trim you

will want curved and thinner the better, a mine access road you may want to use a thick curved for durability but also the

cutting action of a curved blade. Tungsten tip blades are great if you are grading ground that is particularly hard to penetrate.

Serrated are an option to Tungsten tip but I am not sure how wear life compares.

About how to choose a grader blade. It's really dependent on your application and what you are using the grader blade

doing. A mine working environment will generally use thick flats to maintain haul roads, road building and final trim you

will want curved and thinner the better, a mine access road you may want to use a thick curved for durability but also the

cutting action of a curved blade. Tungsten tip blades are great if you are grading ground that is particularly hard to penetrate.

Serrated are an option to Tungsten tip but I am not sure how wear life compares.