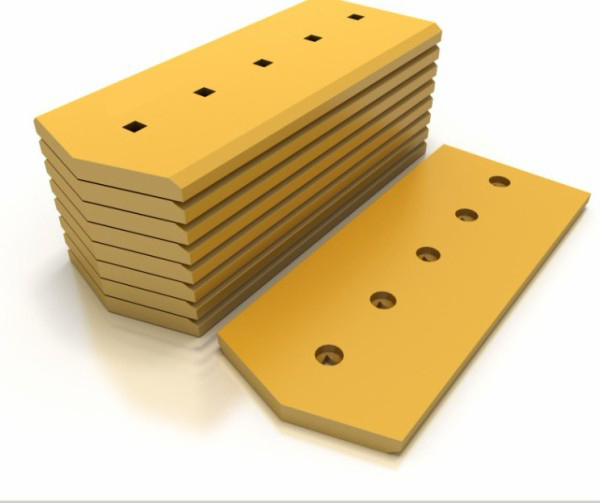

The bulldozer ripper shank which produced abroad don’t use the traditional production process any more, the parts just need a little machining, make the parts have very cheap price and good quality.

Most of the construction machinery factory arrange the production based on the technique of 80s BC, during the past thirty years, all these factory have a tiny space in the world construction machinery market, but still have a big distance with the top construction machinery in USA and Europe.The ripper shank in china produced by the traditional production process, the production scale is small and directly cut from the steel plate, it waste a lot of raw material, the utilization is lower and the cost is high, can not afford the need of the domestic market, and can not have the ability to complete with the factory abroad when we make the export business.

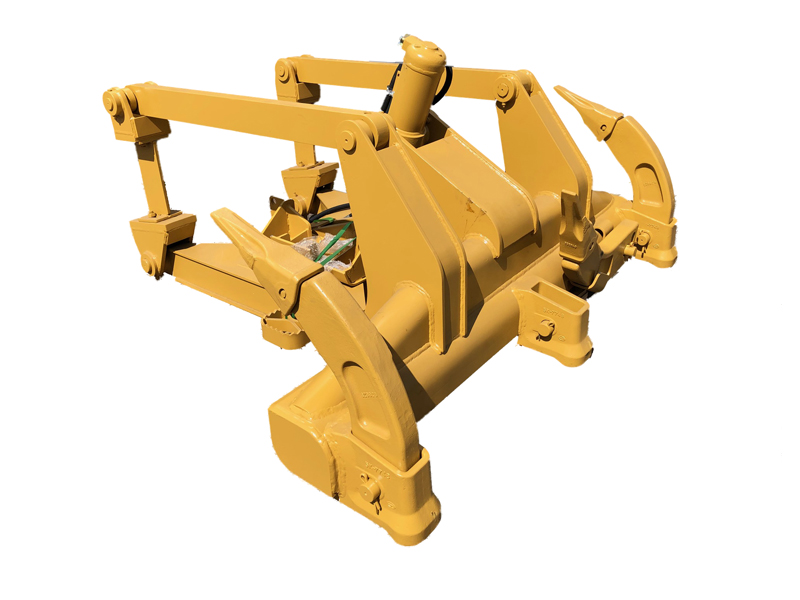

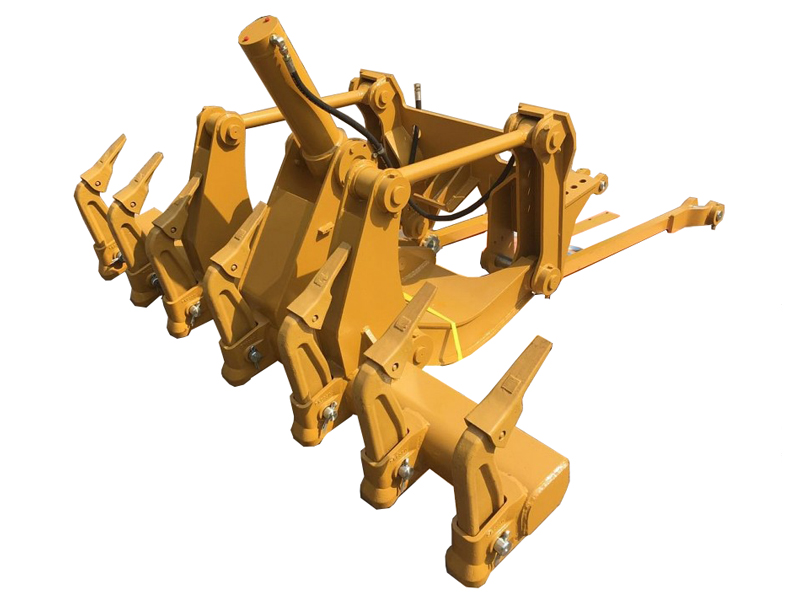

A new development chance for the construction machinery parts is coming because of the rapid development of china’s economy and economic recovery of the world market.Right now the manufacture of bulldozer ripper shanks in china have lower production efficiency and the facility is very old. We have to keep making technical innovation, lower the production cost and increase the production output match the need of our customers in the worldwide.

As far as I am concerned, the factory in Europe produce about 10000 PCS every year, and now we could only produce 1200PCS one year, can not cover the need of the worldwide market.So we decide to making the forging ripper shanks to match the need of our customer.

The final dimension of parts are more influenced by the forging process, the strength and direction of the hammer is the most import factor when we forging the ripper shanks.In the trail production, we have make a lot of experiment on the hammer, and this make we produce the ripper shanks more easily later.

The bulldozer ripper shanks are wear parts, by change the traditional production process, the use ratio of the raw material increased 30%, and production efficiency have increased 30%.

So we decided to make the ripper shanks by the forging process,increase the mechanical property and life span of the ripper shanks.

Most of the construction machinery factory arrange the production based on the technique of 80s BC, during the past thirty years, all these factory have a tiny space in the world construction machinery market, but still have a big distance with the top construction machinery in USA and Europe.The ripper shank in china produced by the traditional production process, the production scale is small and directly cut from the steel plate, it waste a lot of raw material, the utilization is lower and the cost is high, can not afford the need of the domestic market, and can not have the ability to complete with the factory abroad when we make the export business.

A new development chance for the construction machinery parts is coming because of the rapid development of china’s economy and economic recovery of the world market.Right now the manufacture of bulldozer ripper shanks in china have lower production efficiency and the facility is very old. We have to keep making technical innovation, lower the production cost and increase the production output match the need of our customers in the worldwide.

As far as I am concerned, the factory in Europe produce about 10000 PCS every year, and now we could only produce 1200PCS one year, can not cover the need of the worldwide market.So we decide to making the forging ripper shanks to match the need of our customer.

The final dimension of parts are more influenced by the forging process, the strength and direction of the hammer is the most import factor when we forging the ripper shanks.In the trail production, we have make a lot of experiment on the hammer, and this make we produce the ripper shanks more easily later.

The bulldozer ripper shanks are wear parts, by change the traditional production process, the use ratio of the raw material increased 30%, and production efficiency have increased 30%.

So we decided to make the ripper shanks by the forging process,increase the mechanical property and life span of the ripper shanks.